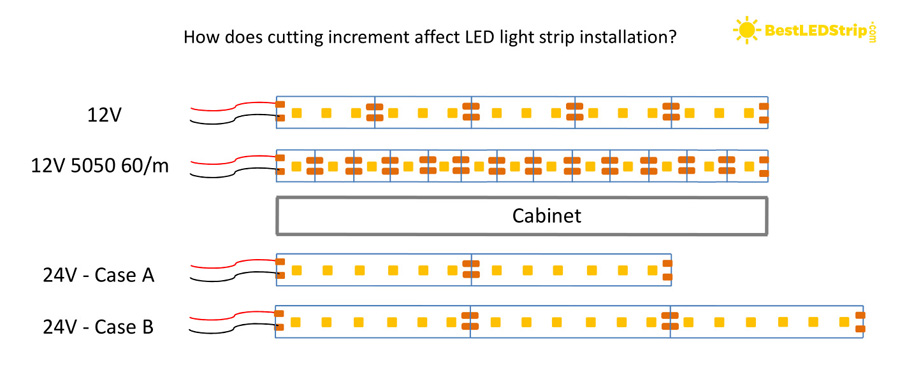

12V vs 24V LED strip lightAlthough the 12V and 24V LED strips are all low voltage LED strip lights, there are significant differences such as cutting increments, luminous efficacy, suitability for long run installation, requirement for LED controllers and power supplies, etc. When you don't know how to choose between 12V and 24V strip lights, you can read this article.  Cutting incrementThe LED strip lights are made by connecting a plurality of minimum cuttable circuit units. The minimum cuttable unit is known as cutting increment. Under the condition that the LED density is the same, the length of the cuttable unit for a 12V LED strip light is generally half of that for the 24V LED strip. For example, RGB strip lights with the density at 60 LEDs/meter, the cutting increment is 2 inches(51mm) for 12V version, and 4 inches for 24V version. Most LED strips use LEDs that have a voltage 2.7-3.3V DC. Under the 12V voltage design of LED light strip, one cuttable circuit unit (cutting segment) can arrange three light sources(LEDs). The remaining voltage is shared by resistors and other components. This is the so-called Three LEDs One Cut, a technology term for the cutting increments of LED light strip. Because there will be an inevitable voltage drop along the strip, the length of the LED strips consisting of multiple 12V cuttable units will generally not exceed 16.4 ft (5 m). Significant voltage drop will occur if it exceeds 16.4ft(5m). Under the 24V voltage design, one cuttable circuit unit can arrange six LEDs, and the remaining voltage is shared by resistors and other components. This is the so-called Six LEDs One Cut. Similarly, due to voltage drop issues, multiple 24V cuttable units typically can be connected to make a light strip with the length up to 32.8 ft (10 m). How does the cutting increment affect the LED strip light installation?Since the LED light strip has a cutting increment, cutting LED strip is limited to only be cut at the pre-marked places along the strip. This limitation affects how the LED strip lights are installed, specifically for the length of installation.  It could be a right match of cutting line with the application surface for 12V LED strip lights, as shown in above picture. For 24V LED strips, it could be more complicated. If the mounting surface ends right in the middle of a cuttable segment, there are two options for the installation length of the light strip. Either one less cuttable segment as the 24V - Case A in above picture, resulting in 1/2 segment length of the mounting surface without LEDs, or one more cuttable segment as the 24V - Case B in above picture, causing 1/2 segment to be beyond the mounting surface. So the length accuracy requirements of your installation can affect your strip light choice. If the cutting increment of 24V LED strip lights is too long and causes inconvenience to your installation, you can choose 12V version. In order to meet the requirements of the installation accuracy, we have specially customized 5050 white light strip. Its cutting length is very short. The 12V 5050 white LED strip is amazingly able to achieve One LED One Cut, a cutting increment of 0.67 inch (17mm). The 24V 5050 white LED strip is Two LEDs One Cut, a cutting increment of 1.34 inch(34mm). The cutting increments of these two versions are much shorter than the usual 2 inches or 4 inches cutting increment of normal LED strips and provides the most accurate length for your installation. The characteristics of this type of LED are: the LED chip size is large, the light-emitting surface is large, and the CRI is higher than 95. LED strip luminous efficiencyBetween the two versions of low voltage LED strip lights, the luminous efficiency of the 24V LED strip is higher than that of 12V LED strip. Usually, the LED strip circuit has resistance and generates heat. The dissipated heat is the part of the energy that is wasted. If the power of the two strips is the same, the strip light that wastes less power has the higher luminous efficiency, because more electric energy is actually used to emit light. Under the same LED density, same length, and same wattage, the 12V LED strip light will draw twice amount of current as the 24V LED strip. For example, a 5m long LED strip with 120 LEDs per meter has the power 50 W. The current with the 12V design is 50W/12V = 4A, while with the 24V design is 50W/24V = 2A. The larger the current is, the more heat is generated on the circuit, the more energy is wasted by form of thermal energy, the less energy is actually used to emit light. Therefore, the luminous efficiency of the 12V LED strip is lower than that of 24V. Which one is more suitable for a longer run installation?Typically 24V LED strips are the better low voltage LED strip lights for longer run installation. For LED strips of the same length and the same LED density, the voltage drop of 12V is larger than that of 24V. As in the above example, the current of the 12V 50W light strip is 4A, and the current of the 24V strip is 2A. Due to the smaller current drawn, the 24V LED strip requires a smaller gauge for the conductors. The 12V LED strip light draws a larger current, and the electronic components on the strip have resistance, therefore the shared voltage is higher, and the voltage drop is larger compared to the 24V strip. 24V LED strip has the relatively smaller current, and the voltage drop is smaller. Due to the voltage drop, the maximum continuous run length of the LED strip is inversely proportional to the current, that is, the smaller the current is, the larger the maximum continuous length. Therefore, the maximum continuous run length of 24V LED strips typically is twice as that for 12V LED strips. The 24V LED strip draws smaller current. If there are multiple light strips parallel installed, the total current is only half of the 12V. This is a factor to consider in the actual installation. If the current limit at the power feed point is small, 24V is your better choice. BrightnessThe brightness of the 12V LED strip light will only be up to a level and cannot be very high. The number of LEDs ranges from 30 to 60 per meter. By electrics theory, the voltage drop is larger for the low voltage LED strip light of 12V, the power cannot be designed to be high, so the brightness will not be very high, even with high-efficacy LEDs. If the power is high, the brightness will decrease greatly along the strip. So the 120 LEDs per meter design can only choose 24V as operation voltage. If your project does not require high brightness, 12V is also a good choice. Power supply optionsWhether it is a 12V power adapter or a 12V professional power supply, 12V power sources have more choices on the market than 24V power sources, and are easier to find as well.

Recommended Reading�� LED strip controller selectionUsually the LED controller is universal for 12V or 24V light strips. RGB LED controllers usually work for both 12V and 24V RGB strip lights. But there are still some power differences. For example, a 6A controller is at 12V operation voltage, its power is 72 watts, while at 24V operation voltage, its power is 144 watts. LED strip light accessories for installationInstallation accessories such as LED strip light connectors and LED aluminum extrusions, typically work well for both 12V and 24V strips. Application range12V DC LED strip lights are generally more widely used than 24V strips. Many electrical systems operate on 12V DC. For example, many batteries for vehicles, RVs and boats operate at 12V DC, which makes it easy to handle these applications with 12V LED strip lights, because no additional transformers or power supplies are needed to convert the voltage. They can be directly installed into the electrical system. For more information about how to wire LED strip to power supplies, please see LED strip light installation guide: step by step installation instruction. 12V LED strip lights for cars12V LED strip lights are widely used for cars, mostly because that the cars have limited space and the 12V LED strip is so low profile that you almost don't notice it exists. Also it is easy to control the 12V RGB light strips with Bluetooth controller, so you can enjoy music sync with color changing lighting. 12V LED strip lights RVMany RV owners want to replace the existing lights with different color temperatures or colorful RGB lights. 12V LED strip lights work perfect for the job . As they are flat and flexible, 12V LED strips save much space for the RVs, at the same time deliver remarkable lighting. Waterproof 12V LED light stripsBoats and yachts sail on the sea. The air on the sea surface is full of moisture and wet. Waterproof 12V LED strip lights are designed for wet environment. 12V RGB LED strips are great choice for creating atmosphere lighting. Using LED controllers, you can set any colorful lighting change modes as well as sync with music on your smart phone. It can even sync with sound, like when people sing happy birthday to you! In summary, if you are new to LED strips, or just install one or two strips(16.4ft or 5m, to 32.8ft or 10m long), or the accuracy of the installation length is important, you choose 12V LED strip lights. If you have a big project and the installation length is long, then 24V is a better choice. For longer distance, larger lumen output, especially for large installation, the 24V LED strip is significantly better than the 12V LED strip because of lower line losses, fewer feed points, and easier installation. This is not a requirement, but a very good rule. |