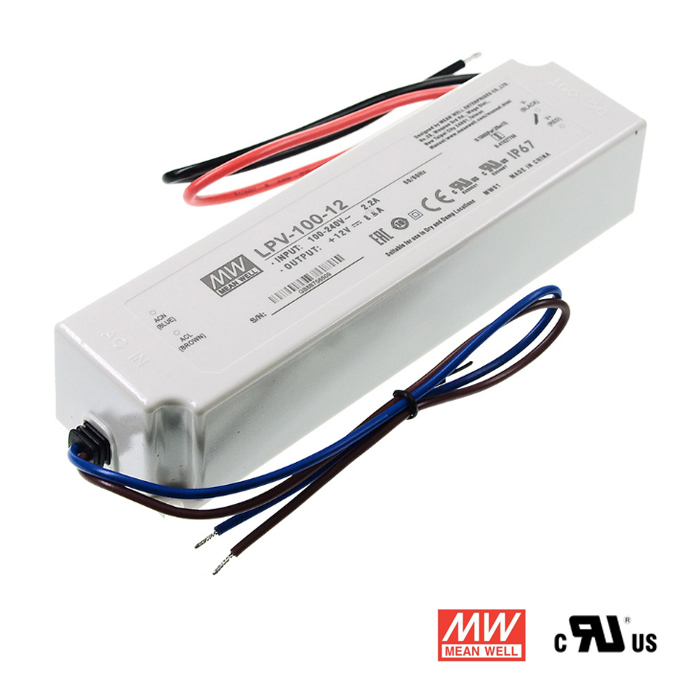

LED Power Supply, 12V and 24V LED TransformerLED power supply is the one of the most important parts for LED lighting project. It is also called LED transformer or LED driver. We supply all kinds of UL listed 12V and 24V LED power supplies. In this article we also help you choose and buy the right LED power supply for your LED strip lights and other LED lights. These LED power supplies come with the best quality, high PFC and high efficiency. Some are waterproof or class 2 category.

Recommended Reading:  12V LED Power SuppliesHigh quality 12V LED power supplies, suitable for small to medium scale LED light installation. UL listed, CE.  24V LED Power Supplies24V LED power supplies, from 60W to 600W & higher. Suitable for medium to large scale LED light installation. UL listed, CE.  12V 24V DC Power AdaptersReliable and durable switching power adapters, 12V and 24V. UL listed, Class 2, with CE and RoHS. 24V LED Power Supplies

12V LED Power Supplies

12V 24V DC Power Adapters

The major factors to consider when choosing LED power supply for your LED lighting projectsFirst, the application environment.

Answers to these questions can tell the application environment of the LED power supply. The environment determines different types of LED power supplies that are suitable for the requirements of the environment. For example, if you install waterproof LED strip lights in outdoor application or in wet or humid areas, you should choose a waterproof LED power supply with IP rating 65, or 67 better.  The IP rating for LED power supply has two digit codes that indicates the ingress protection(IP) level. It is used to indicate the sealing effectiveness of the power supply enclosures. The more effective the sealing is, the better the enclosures protect against intrusion from solid particles (tools or dust etc) and moisture. For example, IP 65. The first digit 6 means it is dust tight. The second digit 5 means it can resist water jets of 30 kPa pressure at distance of 3 meters. The first digit ranges from 0 to 6. The second is from 0 to 9. The higher the better. Another environment factor is the temperature. LED power supply operates at the best efficiency withint a certern range of temperature. Power supply generates heat when it is running. Heat built up around the power supply will cause its effiency to decrease. In the worst case, it will cause failure of LED power supply if overheated for an extended period of time. Providing good ventilation for power supply by using heat sink or fans is the best practise. If not availabe, at least make sure don't put LED power supply in a too tiny enclosure.

Second, the input and output voltage of LED power supply. Another important factor is the output voltage of the power supply. The output voltage should exactly match the input voltage of your LED lights. Most LED strip lights operate on 12V or 24V DC. So we choose 12V LED power supply for 12V LED strip lights, 24V LED power supply for 24V LED strip lights.

Third, the wattage needed. For example, you want to use one LED power supply to provide power for five reels of LED strip lights. Each reel of LED strip has a power of 50Watts. What wattage of power supply do you need? Five reels LED strips have total power of 250W. Giving it a 20 percent cushion, it is 250W x 1.2 = 300W. So you need to buy an LED power supply with at least 300 Watts capacity. If the power supply has 400Watts, you still can use it for your 250W project with no harm, but it is more expensive than the 300W power supply.

Fourth, dimmable or non dimmable LED power supply

Fifth, constant voltage or constant current? Certain LED lights require an LED power supply with constant current output. Constant current LED power supply provide a fixed output current that is typically indicated in amps. The voltage output is in a range and will be variable according to the number of LEDs that are used. Make sure the voltage range covers the required voltage of the LED light circuit. As the power supply provides constant current, the LED lights will maintain a constant brightness level. So some commercial LED signs and LED displays use constant current power supply.

Sixth, UL listed or other safety certifications A quality LED power supply can ensure extended and steady operation with high efficiency for the whole LED lighting system. It plays a vital role in prolonging lifetime of light fixture, saving energy, and lowering maintenance costs. Due the energy-saving, flexible in design, and long lifetime, LEDs have been fast replacing incandescent and fluorescent lights in indoor and outdoor applications. In order to make full use of the high efficacy and long lifetime of the solid-state lighting devices, you need choose proper power supplies that provide appropriate power for your LEDs. LED Power supply knowledge is further explained in details below to help you make wise decision on selection and purchase. 1. What are LED power supplies? LED power supplies are power transformers that convert power to designated voltage or current that are suitable for the applied LED products. In general, the input of LED power supplies includes high voltage AC, low voltage DC, high voltage DC, low voltage high frequency AC, etc. In terms of current output, some LED power supplies are constant current sources that change voltage as the LED forward voltage changes. The core components of the LED power supply include a switch controller, an inductor, a switching component, a feedback resistor, an input filter component, an output filter component, and the like. According to the requirements of different occasions, there are also an input overvoltage protection circuit, under-voltage protection circuit, LED open circuit protection, over-current protection circuit and so on. However, LED strip circuits are designed to place LEDs in string, which controls the current flowing through the LEDs with resistors or other current control components. So most LED strips require a constant voltage power supply. LED power supply was the term that has been used to refer an AC-DC power source that provides a constant voltage output, while LED driver was the term referring to an LED power source that provides a constant current output. Now, the terms LED driver and LED power supply are more and more used interchangeably. 2. What is a quality LED power supply?

2-1. High reliability.

2-2. High efficiency.

Why do LED power supplies require high efficiency?

2-3. High power factor.

What is PF? Why high PF? What is PFC? Reactive power is the power consumed by inductors and capacitors in the circuits. A power system requires both active power and reactive power to work properly. The power factor is the grid's load requirements. The high power factor will greatly reduce the load of the power supply line. For example, in the city at night, the amount of illumination is large, and the similar load is concentrated. The LED power supply with high power factor can reduce the load of the power supply line, reduce the loss, and ensure the stable operation of the lighting products. Low power factor means low power efficiency. The lower the power factor, the higher the proportion of power consumed in the distribution network. If the low power factor is not corrected, it would require higher reactive power, and the utility facilities must provide much more than the active power. Higher reactive power results in the need for larger generators, transformers, and transmission lines to compensate for losses. PFC-enabled LED transformers can improve their energy use, reduce losses and reduce harmonics in the grid.

2-4. Driving method. The other is the direct driving method for the constant current supply and the LEDs are operated in series or in parallel. This method has the advantage of lower cost but offset by poor flexibility. It needs to solve the problem of one segment of LEDs failure without affecting the operation of other LEDs. These two methods coexist. The multiple constant current output method is superior in terms of performance, and more in line with actual needs. It may be the mainstream direction in the future.

2-5. Surge protection. Some surges will cause LED damage, so that the power supply and lamps need to be frequently replaced. Therefore, good surge protection is also a must for an excellent LED driver.

2-6. Protection function. 3. How to assure the quality and reliability of LED power supply?3-1. Standardized professional design process, engineering prototype, small batch trial production. 3-2. Reasonable design margin for components. 3-3. Select high-quality components such as electrolytic capacitors, ICs, power semiconductors, magnetic components, etc. 3-4. Strict quality control and test procedures to perform stress analysis, EVT, SVT, DVT, MTBF, and other experimental verification.

For LED strip light installation, please see following readings that are very helpful: |