LED strip light power supplyHow to choose LED strip light power supply? LED strip light power supply, also known as LED strip light transformer, is the very important part for correctly installing LED strip lights. LED light strips are low-voltage devices that require a low voltage LED power supply or LED driver. The right LED strip power supply is also crucial for LED strip lights to achieve the best performance. Using the wrong LED power supply will not only damage the light strips, it will also damage the power supply itself. In addition, too weak a power supply can cause overheating. So, be sure to follow this step by step guide to choose the right LED strip light power supply.

Recommended Reading: Step 1. Determine to use LED Power Supply or power adapter.Both switching power supply and adapter are widely used as LED strip light transformer. The project scale and installation method determine which one to choose. Many people want to find a 5m LED strip power supply or 10m LED strip power supply. Here we need to know that it is not the LED strip length that determines what power supply to buy. It is the wattage of the LED strip. Because LED strip lights are designed different wattage per meter or per foot. Power Adapter. The basic principle is that if you need at most a 5m (16.4ft) LED strip or two 5m low-power LED strips (total 10m LED strip, say 40W x 2= 80W), choose the power adapter. Because it is easy to wire and install. For example, install the LED strip light under cabinet for 2m (6.56ft) or 3m (9.84ft) long, the output of a power adapter is good enought for provider power for the strip. Usually you don't want people to see the LED strip light transformer. Because the power adapter is small, it is easy to hide even for limited spaces.

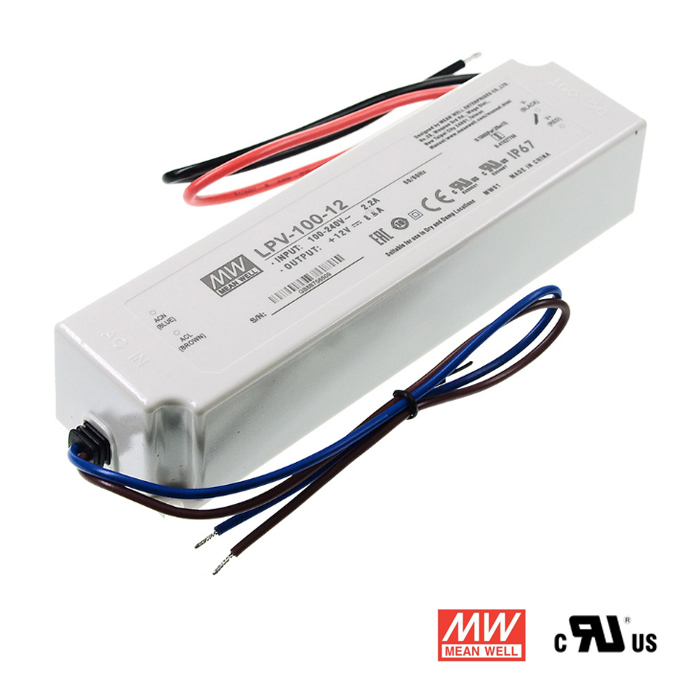

Recommended Reading: LED Power Supply. If you need to install more and longer run LED strips, it is better to choose the switching power supply, because in general, the switching power supply is relatively large in power output, suitable to be used as LED strip light transformer that is able to provide enough power for multiple or long run LED strips. Switching power supplies also generally perform better for big projects and are more efficient in power conversion. Step 2. Choose the correct voltage.

2.1 Correct output voltage, 12V or 24V DC. Other important factors to consider when buying 12V or 24V LED strip light power supply. Current is a factor to consider for LED strip installation and the choice of power supply. For 12V LED strip and 24V LED strip of same wattage, the 24V LED strip draws only half the current as the 12V strip does. For example, consider the current load of the circuit when installing strip lights. If the current load at a power feed point is designed at maximum 18A and other appliances have used 14A, then 4A is left for the feed point. If you choose 12V LED strip power supply, the 12V strip lights may bring a current load over 4A. At this time, you need to select 24V light strip, and the power supply naturally needs to be the 24V version. The choice of wires is also different. At 24V, the current of the circuit is small, and the wires can be chosen for smaller gauge specifications. Our LED strip lights have clear specification for the operation voltage. Choose the LED strip power supply for the same voltage.

2.2 Determine the right input voltage. So, make sure the input voltage range covers your electricity voltage. For example, the LED strip power supply with an input voltage range of 100 - 240V can be used for homes that supply 120Vac, but does NOT work for properties that supply only 277Vac power. A wider input voltage range of power supply is needed. Step 3. Check if you need constant current or constant voltage power supply.Do I need a constant current power supply for LED strip lights? LED strip circuits are designed to place LEDs in string and control the LED current via resistors or other current control components. So, most LED strips require a constant-voltage power supply. Even with current controlled LED strip lights, the circuits are also designed to use constant voltage power supplies. Step 4. Calculate the wattage of LED strip and determine the output of the LED strip light power supply needed.Next, calculate the length of the LED strip to be installed and multiply by the power per meter for the LED strip. For example, you want to install a 11.5ft (3.5m) LED strip with a power of 16 w/m, the light strip power is: 3.5m x 16 w/m = 56W. Then, determine the power of the required LED strip light power supply. It is not recommended using power supply to its full capacity as this will cause the power supply to heat up and shorten its life. Expect to choose at least 20% more capacity. For example, the power supply for the above LED strip should be at least: 1.2 x 56W = 67.2W. However, there is no power supply at exact this specification. Therefore, we choose the next level, e.g., higher output power supply, 72W. An LED power supply with higher output does not damage the LED product because it consumes only the power needed. Step 5. Check to see if you need dimmable or non-dimmable LED power supplies.Most LED dimmers and controllers are 12V or 24VDC, and need to be installed between the power supply and the light strip, requiring a non-dimmable power supply. In other words, the dimmer or controller is installed after the driver or power supply. However, if you plan to install a new AC dimmer before LED driver, or if you want to take advantage of the already installed TRIAC dimmer switch, you'll need a dimmable power supply. That is, the LED dimmer is installed before the power supply. People often say that the use of the existing TRIAC dimmer is suitable for a fast and cheap installation for both new and retrofit jobs. This statement is inaccurate for the installation of LED strips. Why? Because the dimmable power supply is much more expensive than a non-dimmable power supply, and the LED dimmer for the light strip is not expensive. Therefore, the use of the existing dimmer was originally to save the money, but the expensive dimmable power supply will offset the cost savings, and may cost even more in total. Step 6. Determine if waterproof LED strip light power supply or non-waterproof is needed.It is the location where the power supply is to be placed that determines the selection of waterproof or non-waterproof power supply. Waterproof or non-waterproof LED strips themselves do not determine the IP rating of the power supply. When installing and using LED strip lighting in outdoor or wet environment, you must pay attention to the IP rating of the power supply and LED strips. If the power supply needs to be placed in outdoor or humid environment, use a waterproof power supply, at least IP65, IP67, or even higher waterproof level. These power supplies have a weatherproof enclosure and are therefore suitable for outdoor use. If the LED strip is installed outdoors or in a humid environment, but the power supply can be installed in a dry environment, then you can choose non-waterproof power supply. Step 7. Check out the safety protection function.For safety reason, LED strip light power supply should have protection functions, such as over current, over-temperature, short-circuit, open-circuit, etc. These safety precautions cause the problematic power supply to shut down. These protection features are not mandatory. However, if you want to use it safely in the event of a problem, you should only install a power supply with these protection features. Step 8. Look for the UL listed certification. Both the power supply and the power adapter should be UL listed. For small applications, a class 2 power source is preferred. UL recognized power supplies have passed certified lab examination and tests according to safety and function standards. It gives extra confidence in quality. LED lighting product power standard UL8750 includes class 2 in its own standards. Class 2 certified power supply means that the power circuit is safer, and it has lower risk of causing a fire initiation or posing an electric shock to the human body. Be aware that some LED strip light power supplies on the market do not have UL certification or have a fake UL certification. When purchasing power supplies, use proper caution. Due to the product knowledge and expertise, only factories with knowledgeable human resource have the ability to develop quality products and control the quality. The switching power supplies or adapters manufactured by qualified factories are safer to use. We choose the power supply from famous brands such as Mean Well for LED light strips, and they all have 3-5 years or even longer warranty. Follow the step by step guidance above, buy the right LED strip light power supply you need for your project. The right power supply not only provides the power needed, but also the electrical safety when using, and the uninterrupted enjoyment of the lighting. How to connect LED strip lights to power supply?1. Connect the LED light strip to the power supply.After selecting the appropriate LED strip light power supply, we will connect the red and black wires of the LED strip to the corresponding terminals or leads of the power supply. Here, you need to pay attention to the positive and negative poles of the light strip. They must correspond to the positive and negative poles of the power supply output. (Sign + or +V for red line; sign - or -V or COM for black line).

Recommended Reading:  How to wire LED strip light to power supply?The figure below shows several examples of wiring LED strip lights to the power supply.  Warm white, neutral white, and cool white LED strip lights can be connected directly to power supplies in the following ways. A. The LED light strip and power supply have matching DC male and female connectors, which can be directly inserted into the connection. B. The power supply has a DC male connector, and the light strip has a pig tail lead. A coaxial barrel and screw terminal connector is required. C. The light strip has pig tail leads and is connected to a common switching power supply. Simply secure the pig tail leads with screw at the power supply output terminals. If it is a monochrome light strip with a DC connector with two wires, you can cut off the DC connector, strip the wire and connect it to the power supply. D. The light strip has a pig tail lead. And the LED strip power supply also has a pig tail lead, such as the Mean Well HLG-240-24. You can use the clip on connectors to connect the leads of power supply and the light strip. You can also use wire-end ferrules to connect, then put on the heat shrink tubing to provide insulation. Clip on connectors and wire-end ferrules are professional and easy connectors that do not require soldering. However, if you use tunable white light strips, 5050 RGB or RGBW LED strips, the light strips need to be first connected to LED controllers, then the controllers are connected to the LED strip light power supply. For more information, please see the LED controller category, which details how to connect LED controller to power supply. Next, all you have to do is connect the LED strip power supply to the 110V home power network. The input of the power supply is generally marked with L (live), N (neutral), and G (ground). If a power supply needs to be connected to the wall outlet, a three-phase power cord is required. Generally, the power supply does not carry this cord and needs to be purchased separately. Note: when you connect LED strips to LED controller or power supply, there are plenty of LED strip connectors that can help you make the connection fast and easy. 2. What gauge wire for LED strips to connect to LED strip power supply?The current load determines the gauge wire for LED strips to connect to LED strip powre supply. There is the situation where the light strip is to be connected to the power supply but there is a long distance between them. At this time, consider installing an extension cord between the power supply and the light strip. When installing the extension cord, pay attention to the gauge specification of the extension cord. A simple rule of thumb can be used to determine the cable cross section for wires: 0.1 mm² is required per ampere of current. For a current of 6A, the measurement result is 0.6 mm². Typically, the next higher standard, 0.75 mm² wires will be selected to connect the components. In RGB strip light applications, the current of the common positive wire is three times the current of each color wire. It must be taken into consideration when choosing LED wires to connect to LED strip power supply. Each color wire has max current 2A, the sum is 6A, so the positive wire is at least 0.6 mm², and the size of each color wire should be 0.2 mm². For this reason, there are some special RGB cables with three thinner color wires and a positive wire of 3 times cross section, for example the wire specification is like this: 3 x 0.25 mm² + 1 x 0.75 mm². This is the case with the design for some of our RGB controllers. If the transmission distance is long between LED strip light transformer and the light strip, you should choose wires with larger cross section to minimize the loss along the line. But soldering with large cross-section wires can be difficult. Imagine soldering multiple wires of 1 mm² cross section to sometimes quite narrow RGB copper pads or even RGBW LED strips. Tips. There are 2 solutions to the problem. 1. Strip the 1 mm² wire and cut about half of the single copper wire. In this way, the portion of the line that is significantly reduced in cross section can be more easily soldered to the LED strip. 2. Take a short (10 cm) wire with smaller cross-section, such as a 0.5 mm², solder it to the LED strip and connect it to the 1 mm² positive wire of the RGBW cable. For connections, you can use clip-on connectors or wire end ferrules and put on heat shrink tubing for insulation. For a very short line, a small cross-section wire is no problem. 3. How to power LED strip?During installation, you need to consider where to put the LED strip light transformer so it requires less transformers to power the LED strips, and hence the cost is less for the project. For 12V strips, it is generally recommended supplying power at least every 16.4ft (5 meters) due to the inevitable voltage drop along the low voltage LED strip. The background is two-fold. On the one hand, the conductor track of the LED strip can only carry a limited load. On the other hand, there is power loss due to the relatively small cross section of the conductor. The result is that the strip conductor track heats up and the brightness decreases at the end of the LED strip if the installation is not appropriate. The above recommended reading about install LED strip lights has very detailed information on where to place the LED strip light power supply, and LED controller if necessary. It is generally recommended to connect at a length of 5 meters for 12V LED strips. If it is a 32.8ft (10m) installation, it is usually easier to supply power from the midpoint. The current is split in two directions from middle, each direction being only 16.4ft (5m) long. Use white light strips such as warm white or cool white LED strips, if you do not install the controllers, you can easily supply power from multiple feed points. Simply connect a 5 meter or shorter wire into the LED strip light power supply. In the case of RGB, RGBW strips or installation with controllers, of course, the wires must be distributed from the controller. If the load exceeds the output of the controller, LED amplifiers should be used. 12V LED Power Supplies

24V LED Power Supplies

12V 24V DC Power Adapters

|