LED Color Color Temperature Waterproof Brightness Input Volts |

Outdoor LED Strip Lights

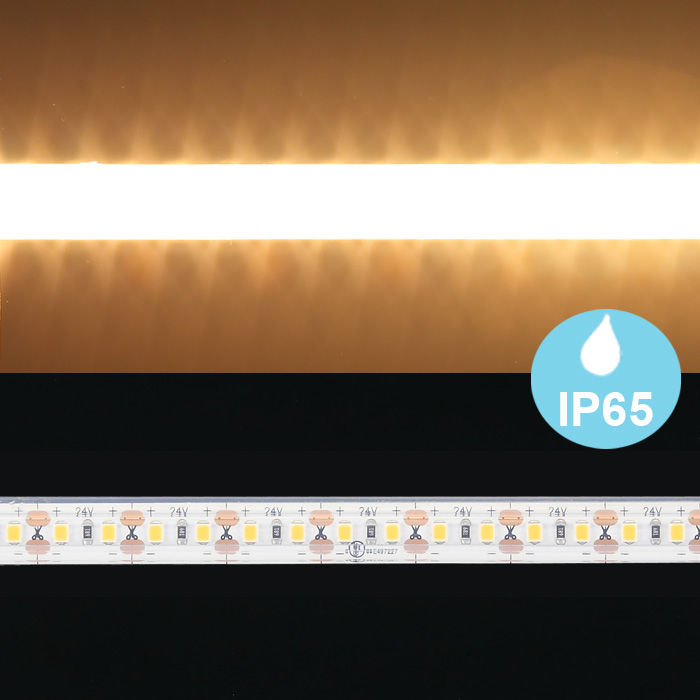

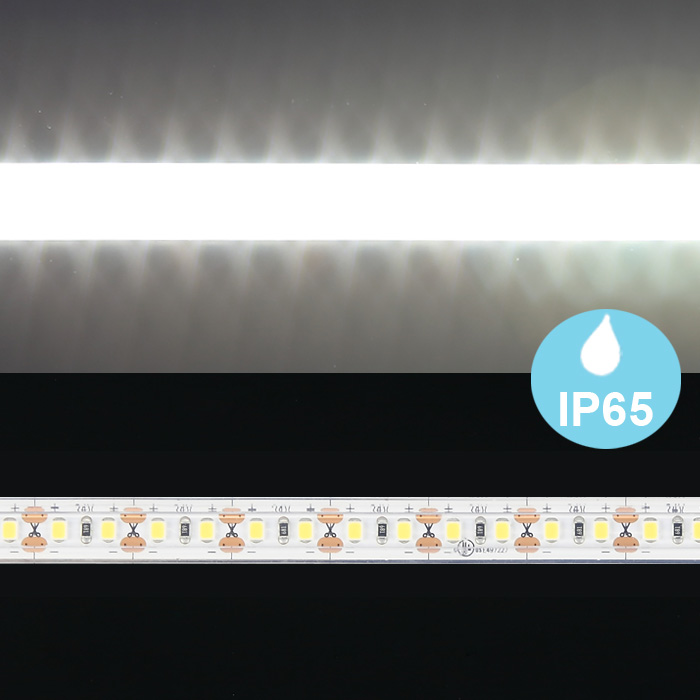

We provide a full range of IP65, IP68 outdoor LED strip lights, including 12V, 24V, RGB, RGBW, RGBCCT color changing, white, red, green and blue. They are for exterior LED strip lighting and indoor applications, for outdoor or dustproof purposes. These outdoor LED strips have been widely used for houses, yard, patio, bathroom, deck, and landscaping. They are the best outdoor LED strip lighting using high quality silicone as waterproof material. Silicone is a healthy material with irreplaceable advantages. It also can be used indoor.

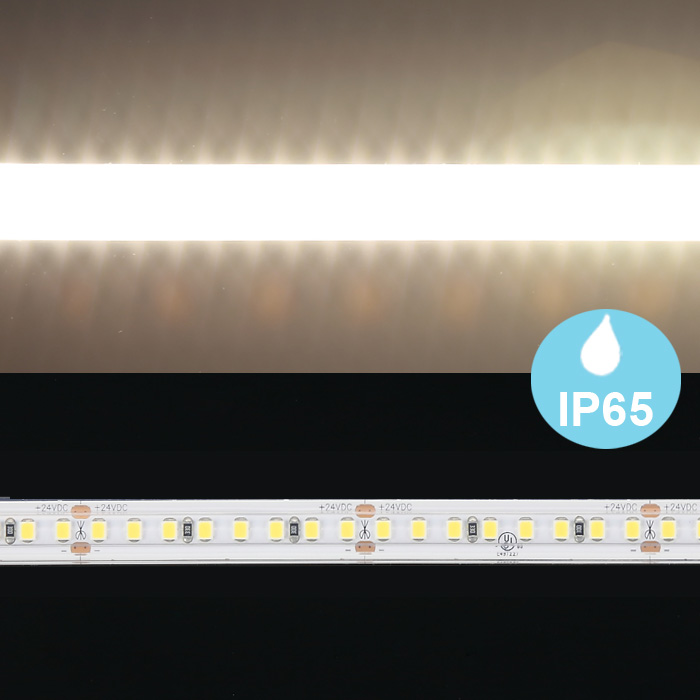

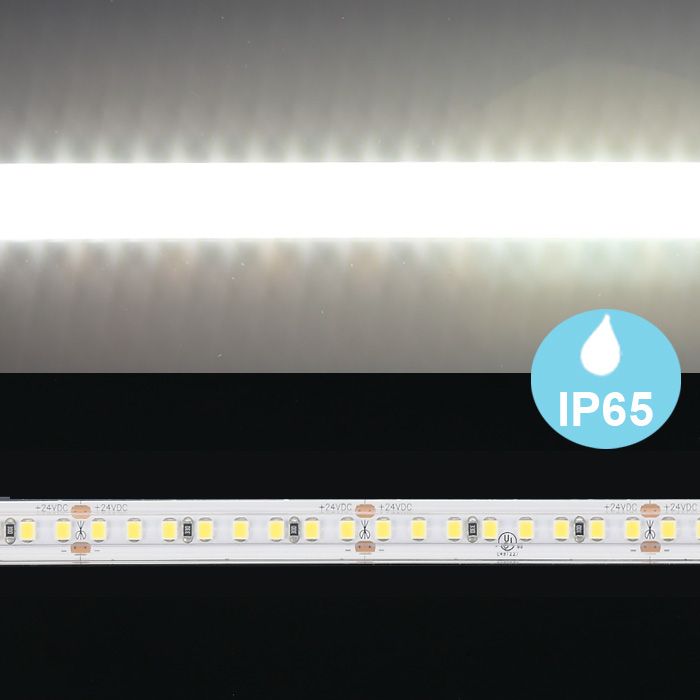

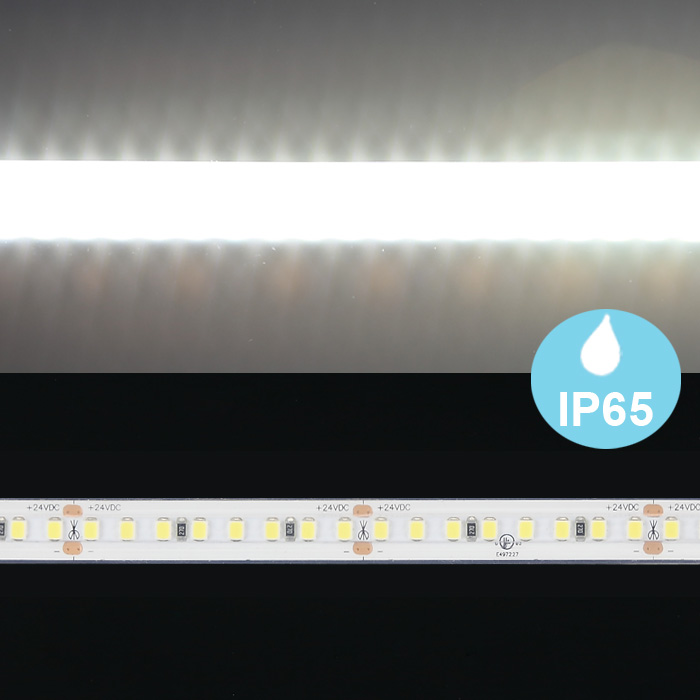

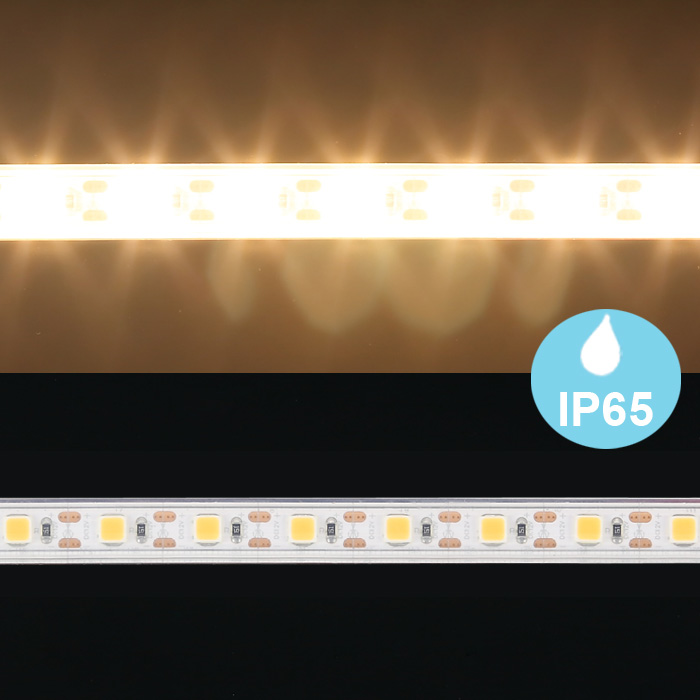

IP65: Completely dust-tight and able to withstand low-pressure water jets from any direction. Suitable for general outdoor use, such as protection against rain and dust. 5-Year Warranty. UL Listed.

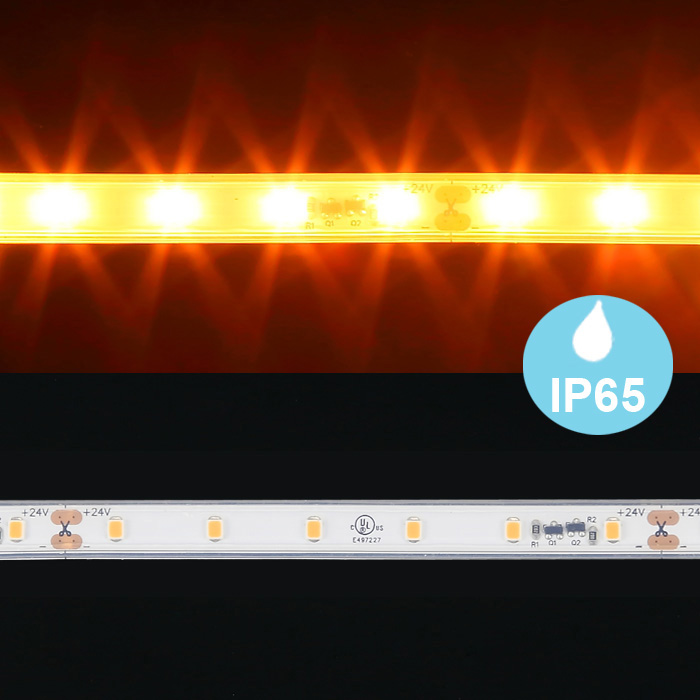

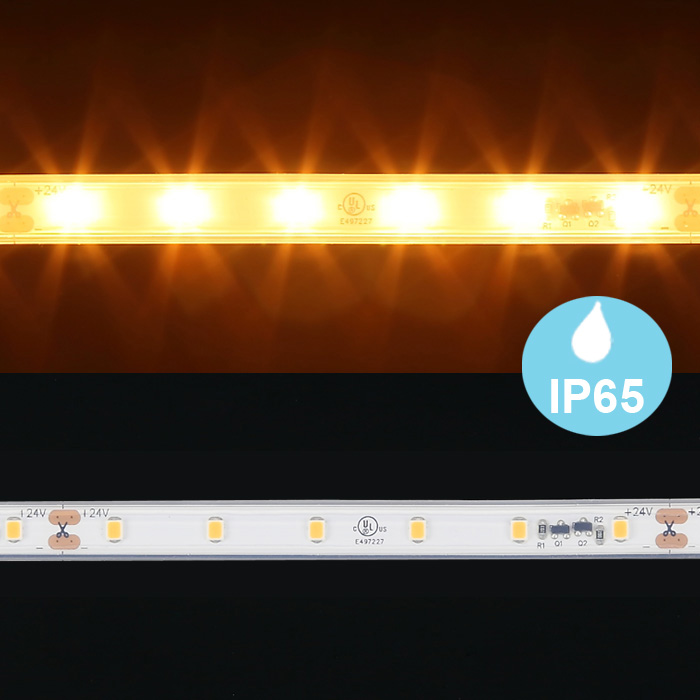

Orange, super warm, warm white, neutral white and cool white. Resistant to rian and water splashes.

Color changing RGB, RGBW, and RGBCCT Tunable White. Withstand weather elements. Outdoor LED Strip Lights - White

Displaying 1 to 24 (of 24 products) -

Brightness Meter

| CRI: 90+ | |

| Lumen: 1346 lm/m | |

| Model: wp2400k-120-5m | |

$95.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 1484 lm/m | |

| Model: wp2700k-120-5m | |

$95.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 1520 lm/m | |

| Model: wp3000k-120-5m | |

$95.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 1668 lm/m | |

| Model: wp4000k-120-5m | |

$95.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 1622 lm/m | |

| Model: wp5000k-120-5m | |

$95.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 1603 lm/m | |

| Model: wp6500k-120-5m | |

$95.00

-

Brightness Meter

| CRI: 85+ | |

| Lumen: 1736 lm/m | |

| Model: wp2700k-128-5m | |

$109.00

-

Brightness Meter

| CRI: 85+ | |

| Lumen: 1797 lm/m | |

| Model: wp3000k-128-5m | |

$109.00

-

Brightness Meter

| CRI: 85+ | |

| Lumen: 2004 lm/m | |

| Model: wp4000k-128-5m | |

$109.00

-

Brightness Meter

| CRI: 85+ | |

| Lumen: 2031 lm/m | |

| Model: wp5000k-128-5m | |

$109.00

-

Brightness Meter

| CRI: 85+ | |

| Lumen: 2020 lm/m | |

| Model: wp6500k-128-5m | |

$109.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 502 lm/m | |

| Model: 1800k-60-10m | |

$138.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 621 lm/m | |

| Model: wp2400k-60-10m | |

$138.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 678 lm/m | |

| Model: wp3000k-60-10m | |

$138.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 769 lm/m | |

| Model: wp4000k-60-10m | |

$158.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 749 lm/m | |

| Model: wp5000k-60-10m | |

$158.00

-

Brightness Meter

| CRI: 90+ | |

| Lumen: 735 lm/m | |

| Model: wp6500k-60-10m | |

$158.00

-

Brightness Meter

| CRI: 85+ | |

| Lumen: 2053 lm/m | |

| Model: wp2700k-160-5m | |

$125.00

-

Brightness Meter

| CRI: 85+ | |

| Lumen: 2141 lm/m | |

| Model: wp3000k-160-5m | |

$125.00

-

Brightness Meter

| CRI: 85+ | |

| Lumen: 2247 lm/m | |

| Model: wp4000k-160-5m | |

$125.00

-

Brightness Meter

| CRI: 85+ | |

| Lumen: 2203 lm/m | |

| Model: wp5000k-160-5m | |

$125.00

-

Brightness Meter

| CRI: 85+ | |

| Lumen: 2264 lm/m | |

| Model: wp6500k-160-5m | |

$125.00

-

Brightness Meter

| CRI: | 95+ |

| Long: | 5M(16ft) Reel |

| Model: | wp2700k-5050-60-5m |

$85.00

-

Brightness Meter

| CRI: | 95+ |

| Long: | 5M(16ft) Reel |

| Model: | wp12v-6500k-5050-60-5m |

$85.00

Outdoor LED Strip Lights - Color Changing

Displaying 1 to 8 (of 8 products) -

Brightness Meter

| Density: 18 LEDs/ft (60/m) | |

| Length: 16ft (5m) Reel | |

| Color: R, G, B, 2400- 6500K | |

$164.00

-

Brightness Meter

| Density: 18 LEDs/ft (60/m) | |

| Length: 16ft (5m) Reel | |

| Color: R, G, B + 2700K | |

$134.00

-

Brightness Meter

| Density: 18 LEDs/ft (60/m) | |

| Length: 16ft (5m) Reel | |

| Color: R, G, B + 3000K | |

$134.00

-

Brightness Meter

| Density: 18 LEDs/ft (60/m) | |

| Length: 16ft (5m) Reel | |

| Color: R, G, B + 4000K | |

$134.00

-

Brightness Meter

| Density: 18 LEDs/ft (60/m) | |

| Length: 16ft (5m) Reel | |

| Color: R, G, B + 5000K | |

$134.00

-

Brightness Meter

| Density: 18 LEDs/ft (60/m) | |

| Length: 16ft (5m) Reel | |

| Color: R, G, B + 6500K | |

> $134.00

-

Brightness Meter

| Density: 18 LEDs/ft (60/m) | |

| Length: 16ft (5m) Reel | |

$95.00

-

Brightness Meter

| Density: 18 LEDs/ft (60/m) | |

| Length: 16ft (5m) Reel | |

$105.00

Best Outdoor LED Strip Lights

-

Eco-friendly Material: Eco-friendly silicone is a non-toxic, harmless material that poses no threat to humans or the environment.

-

Temperature Resistance: Silicone material has excellent temperature resistance, capable of withstanding extreme climates from high to low temperatures. This makes it ideal for outdoor use, ensuring that LED strip lights can operate steadily whether in hot summers or cold winters.

-

UV Resistance and Anti-Aging: Eco-friendly silicone does not age, yellow, or become brittle when exposed to sunlight for long periods, maintaining its flexibility and transparency. This means that LED strip lights can retain their performance and appearance even after long-term outdoor use.

-

High Elasticity and Flexibility: The flexibility of silicone allows LED strip lights to be easily installed in various outdoor settings with different shapes and surfaces, without breaking due to repeated bending.

-

High Transparency and Brightness Retention: Eco-friendly silicone is not only soft but also maintains high transparency, ensuring that LED light is evenly distributed and brightness remains unaffected.

-

Excellent Protection Performance: Eco-friendly silicone LED strip lights have high levels of waterproof, dustproof, and shockproof protection, enabling them to work stably in harsh outdoor environments. This is crucial for long-term lighting in areas like gardens, pools, and patios.

Key Features of Outdoor LED Strip Lights for Residential Use

Illuminate your kitchen with sleek and durable LED light strips. These outdoor light strips provide bright and even lighting for countertops, cooking spaces, and dining areas.

1. Waterproof and Durable:

Outdoor LED strip lights are designed to withstand harsh weather conditions. Choose lights with an IP65 rating or higher to ensure they are rainproof, dustproof, and even snowproof, making them suitable for various outdoor environments.

2. Energy-Efficient and Eco-Friendly:

Compared to traditional lighting, LED lights consume much less energy, saving on electricity bills while providing bright illumination for extended periods. They are ideal for long-term use.

3. Customizable Length and Flexibility:

Many outdoor LED strip lights can be cut to fit specific needs and are flexible enough to adapt to different areas around the house, such as windows, doorways, or pathways.

4. Wi-Fi Remote Control:

Use your smartphone to remotely adjust brightness, color, and turn the lights on or off.

Outdoor LED Light Strips for House

1. House Perimeter Lighting: Installing LED strip lights under the eaves or along the roofline can highlight the architectural features of the house, creating a beautiful outline lighting effect at night, enhancing both the visibility and aesthetics of the house.

2. Pathway and Driveway Lighting: Place LED strip lights along the edges of pathways and driveways to provide safe night-time guidance. The soft lighting ensures visitors can clearly see the road surface, reducing the risk of tripping.

3. Deck and Patio Lighting: Installing LED strip lights under the railings of decks or patios provides soft illumination for outdoor activities at night. This not only enhances the atmosphere for gatherings but also offers a sense of safety for family and guests.

4. Landscape Lighting: Use LED strip lights to highlight key landscape features in the garden, such as trees, flower beds, or garden walls. This not only enhances the visual effect at night but also adds a touch of romance to the garden.

5. Fence and Boundary Lighting: Installing LED strip lights along fences or garden boundaries increases both aesthetics and safety. Illuminated boundaries add depth and dimension to outdoor spaces and also serve as a deterrent.

6. Staircase Lighting: For outdoor stairs, especially those leading to the porch or backyard, LED strip lights can be installed under each step, providing soft lighting and increasing safety at night.

7. Pool and Water Feature Lighting: For homes with pools or water features, IP68 waterproof LED strip lights can be installed along the pool edge or integrated into water features, creating a beautiful night-time lighting effect while enhancing visibility at night.

8. Porch and Balcony Lighting: Installing LED strip lights on porch ceilings or balcony railings adds a modern decorative element. Whether for relaxing or family gatherings, this lighting option provides the right amount of light.

9. Garden Lighting: By installing LED strip lights along garden paths or around flower beds, you can add soft lighting to the entire garden at night, highlighting plants and landscape structures to make the garden more attractive.

Outdoor LED Strip Lighting in the Kitchen

In a kitchen environment, where cooking generates steam, moisture, and grease, choosing the right waterproof LED strip lights is crucial. Waterproof LED strip lights not only provide sufficient lighting but also effectively resist moisture and grease, making them an ideal choice for kitchen lighting. Here are some key points and application scenarios for using waterproof LED strip lights in the kitchen:

1. Importance of Waterproof Rating

Choose LED strip lights with a high protection rating: Kitchens are humid environments, so selecting waterproof LED strips with at least an IP65 rating is essential. This protection level can prevent water splashes, dust, and grease from entering, ensuring the lights work stably in the kitchen for extended periods.

2. Application Scenarios for Waterproof LED Strip Lights in the Kitchen.

-

Under-Cabinet Lighting

Application: Install waterproof LED strip lights under cabinets to provide bright lighting for countertops. This lighting method helps avoid shadows cast by overhead fixtures and enhances the overall illumination in the kitchen, ensuring clear visibility when cutting or cooking. Benefits: Waterproof LED strips can withstand water splashes and grease from washing and cooking. They are easy to clean and maintain.

-

Sink Area Lighting

Application: The sink is one of the most humid areas in the kitchen. Installing waterproof LED strip lights above or around the sink can provide direct light to the washing area, making it easier to clean ingredients and dishes. Benefits: Waterproof LED strips resist water splashes, and their durability and energy efficiency make them ideal for sink area lighting.

-

Kitchen Island and Overhead Cabinet Lighting

Application: Installing waterproof LED strip lights on the kitchen island can enhance localized lighting, especially when preparing food or using it as a dining area. Additionally, installing the lights around overhead cabinets can increase ambient lighting and give the kitchen a more modern and cozy feel. Benefits: The soft light from LED strips improves the kitchen atmosphere, and the waterproof feature ensures stability in high-humidity environments

3. Dimming Feature of Waterproof LED Strip Lights.

Application: In the kitchen, lighting needs may vary depending on the activity. Waterproof LED strip lights with dimming capabilities can be adjusted to high brightness during cooking, and softened during dining or relaxation to create a comfortable atmosphere.

4. Installation and Maintenance

Easy Installation: Waterproof LED strip lights usually come with adhesive backing, making them quick to install under cabinets or on walls. If additional support is needed, using mounting clips can enhance stability. Easy Maintenance: Since the strips are waterproof, their surface is easy to wipe clean, making them especially suitable for kitchens where grease and water splashes are common.

Combining Aesthetic and Functional Outdoor LED Strip Lighting

-

Color and Dynamic Lighting Options: In addition to standard white LED strip lights, outdoor LED strips offer RGB multicolor options that can be controlled via a remote or app. These lights are perfect for holiday decorations or creating a lively party atmosphere

-

Smart Home Integration: Modern outdoor LED strip lights can be integrated with smart home systems like Alexa or Google Home, allowing you to control the lights’ power, color, and brightness through your phone or voice commands, making outdoor lighting more convenient and intelligent.

Benefits of Outdoor Accent Lighting

-

Enhancing Safety: By illuminating pathways, stairs, and surrounding areas, outdoor accent lighting not only beautifies the space but also improves night-time safety, preventing trips and missteps.

-

Increasing Home Appeal: Whether it’s the garden, patio, or pool area, well-designed outdoor accent lighting significantly enhances the aesthetics and comfort of the space at night, adding a special ambiance to family gatherings, parties, or quiet time.

-

Holiday and Special Occasion Decor: By changing the color or style of the lights, outdoor accent lighting can easily be adapted for festive decorations, making it suitable for events like Christmas, Halloween, weddings, or birthdays.

How to Install Outdoor LED Strip Lights

-

Adhesive Installation: Many LED strip lights come with adhesive backing, allowing users to easily stick them to fences, walls, or railings. This adhesive design makes installation simple and quick, perfect for DIY projects.

-

Using Aluminum Channels or Mounting Clips: For areas where more stable installation is needed, aluminum channels or mounting clips can be used to secure the LED strip lights, especially for longer strips or those exposed to weather conditions.

Tips for Choosing Exterior LED Strip Lights

-

Choose the Right Waterproof Rating: If the lights will be exposed to rain or humid environments, make sure to select LED strips with an IP65 rating or higher.

-

Choose the Right Brightness (Lumens): Select the brightness based on your lighting needs. For ambiance, lower brightness is sufficient, while higher brightness is recommended for pathways or security lighting.

-

Choose the Right Color Temperature: Warm white (2700K-3000K) is ideal for creating a cozy atmosphere, while cool white (6000K-6500K) is better for areas requiring bright, clear lighting.

If you want to create a super cozy patio, consider choosing an 1800K orange exterior light strip. It adds a warm, soft ambiance to your outdoor space, perfect for relaxing evenings. This orange 1800K LED light strip has a color temperature close to candlelight, making it ideal for creating a warm, inviting atmosphere.

-

Use Smart Controls: For more control, opt for LED strips that support smart systems, allowing you to adjust the lighting via your smartphone or smart device

12V vs 24V Low Voltage Outdoor LED Strip Lights

1. Applicable Length and Brightness.

-

12V Low Voltage: Ideal for small-scale outdoor lighting applications, typically effective for distances of up to 5 meters. Suitable for accent lighting in areas like garden beds, outdoor stairs, or porches.

-

24V Low Voltage: Suitable for longer outdoor strip lighting installations, extending up to 10 meters or more. It provides stable brightness, ideal for perimeter lighting, wall-mounted lighting, or large outdoor areas..

2. Outdoor Adaptability.

-

12V Low Voltage: Works well for smaller outdoor lighting projects with lower voltage requirements, making it ideal for low-brightness ambient lighting.

-

24V Low Voltage: Maintains brightness over longer distances and adapts to complex outdoor environments, especially for larger areas that need extensive illumination.

3. Voltage Drop and Efficiency.

-

12V: Designed for short-distance, low-voltage installations, minimizing light loss and extending strip life.

-

24V: Suitable for long-term, high-brightness outdoor lighting, reducing voltage drop over longer distances and offering greater energy efficiency.

For places where the 24V version can be used, basically 12V Outdoor LED strip light can also be used. But the reverse is different. In some places, only 12V strips version can be used, such as on cars, RVs, and boats, because the power supply system is 12V.

Compared with 12V strip light, 24V version is better for longer run installation, because its voltage drop is smaller than 12V strip. In addition, 24V version draws less current than 12V, which makes the 24V version better for large-scale installation.

By the way, where indoor versions can be used, outdoor LED strips can generally also be used, and provide protection from dust, particles, incident impact, and other harmful factors.

Outdoor LED Strip Lights FAQ

-

Q: Can outdoor LED strip lights be cut to fit specific spaces?

A: Yes, many outdoor LED strip lights can be cut along designated lines, allowing you to customize the length to fit your specific installation area.

-

Q: How long do outdoor LED strip lights last?

A: Outdoor LED strip lights typically last between 30,000 to 50,000 hours, depending on usage and environmental conditions.

-

Q: Do outdoor LED strip lights attract insects?

A: Unlike traditional incandescent lights, LED lights emit very little heat and UV radiation, which significantly reduces their ability to attract insects.

-

Q: Can outdoor LED strip lights be dimmed?

A: Yes, outdoor LED strip lights can be used with compatible dimmers, allowing you to adjust the brightness and create the ideal ambiance.

-

Q: Are outdoor LED strip lights waterproof?

A: Yes, our outdoor LED strip lights come with an IP65 waterproof rating, making them rainproof and dustproof, suitable for most outdoor applications.

-

Q: Can I install outdoor LED strip lights myself?

A: Absolutely! Our outdoor LED strip lights are designed for easy installation, featuring adhesive backing and mounting clips, making them perfect for DIY projects.

-

Q: Can outdoor LED strip lights be used for RVs and yachts?

A: Yes, outdoor LED strip lights are ideal for RVs and yachts. They provide cozy lighting for RVs when parked and are great for pathways and deck areas on yachts. Their waterproof design ensures durability in marine environments.

Outdoor LED strip lighting combines style, safety, and functionality, adding a glow to your nights while highlighting landscape features and making outdoor gatherings unforgettable. Choose high-quality outdoor lighting products to breathe life into your exterior spaces, providing long-lasting ambiance.

Recommended Reading:

Buy waterproof LED connectors for your outdoor LED strip installation

|